Industrial Electrical Services

Precision.

Partnership.

Performance.

Bremer Electric & Automation delivers precision troubleshooting and root cause analysis to

streamline operations, prevent downtime, and future‐proof systems. Led by DSPS Certified

Master Electrician David Bremer, we combine engineering foresight and lean manufacturing

principles to diagnose bottlenecks, design targeted improvements, and implement solutions that

address root causes—not just symptoms. Our approach spans new upgrades and existing

inefficiencies, ensuring outcomes are scalable, repeatable, and aligned to your goals.

Industries Served

Food & Beverage Manufacturing

• Upgraded automation systems to reduce downtime and improve throughput

• Integrated safety controls for fluid handling and sanitation systems

• Electrical support for regulated environments requiring DNR and FDA compliance

Packaging & Printing Facilities

• Troubleshooting press line failures and optimizing control systems

• Retrofitting legacy equipment to support lean manufacturing transitions

• Electrical upgrades for high-speed production lines

Industrial Fabrication & OEM Support

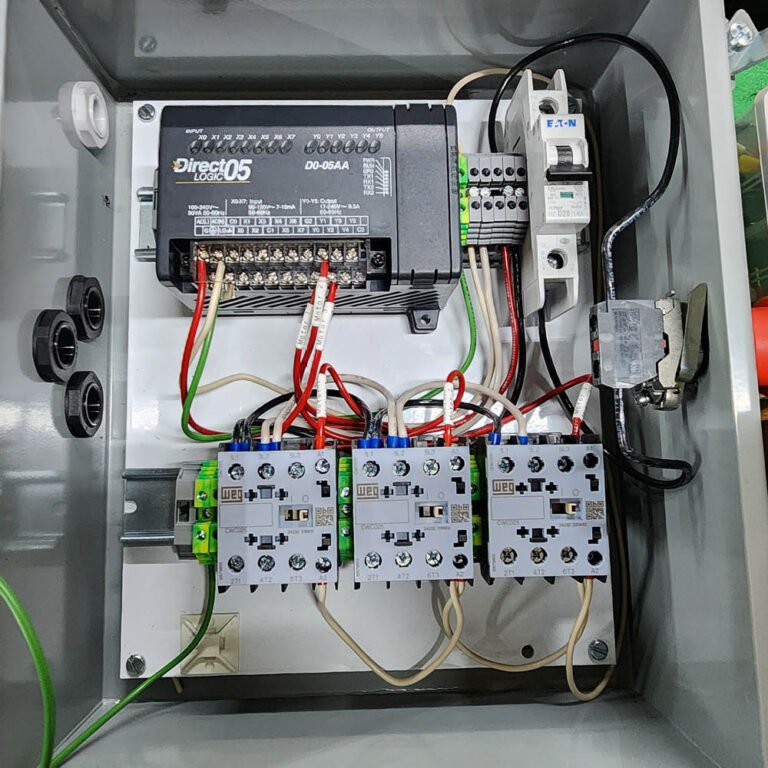

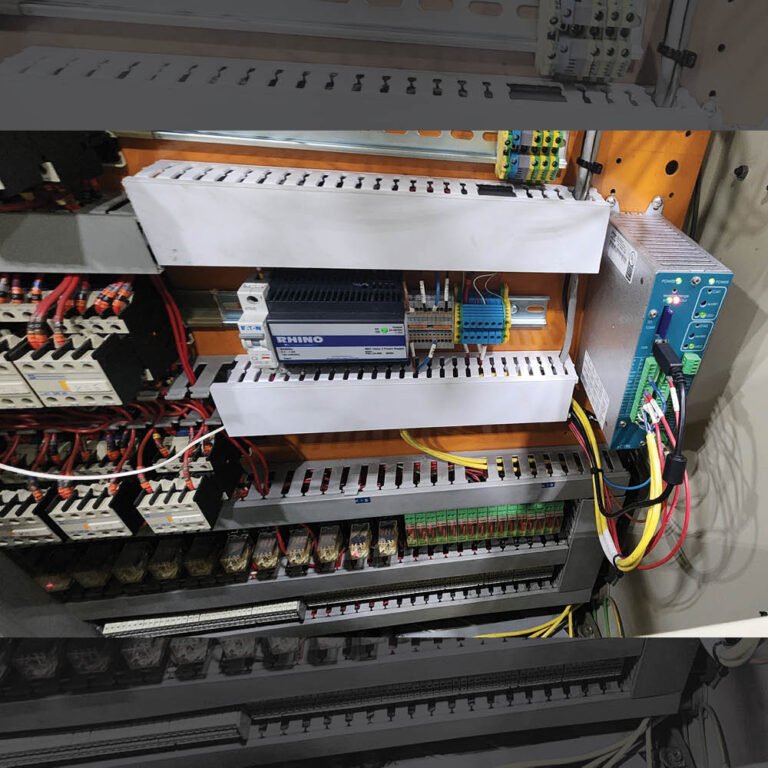

• UL panel compliance and custom control panel installations

• Electrical integration for machine builders and fabrication shops

• Support for prototype testing and system commissioning

Warehousing & Distribution Centers

• Code-compliant installations for conveyor systems, ventilation, and lighting

• Preventative maintenance planning to reduce operational disruptions

• Electrical support for automation and inventory control systems

Process-Driven Manufacturing Environments

• Integration and troubleshooting of pneumatic and hydraulic circuits for automated processes

• Fluid power coordination for material handling and packaging systems

• Electrical upgrades for dust collection, temperature control, and fluid systems

• Documentation and compliance support for OSHA and EPA-regulated operations

• Troubleshooting and optimization of legacy control systems

And More

We happily serve all types of industries. Schedule a walkthrough today!

Our Industrial Services

- PLC Programming & Retrofitting: Legacy system upgrades and modern PLC integration to streamline operations

- Automation Upgrades: Improve efficiency, reduce manual strain, and future-proof your systems

- Integrated Electrical & Fluid Power Controls: Design and integration of electrical, pneumatic, and hydraulic control systems, including custom panels and safety interlocks

- Preventative & Predictive Maintenance: Minimize costly downtime with proactive electrical and fluid power care

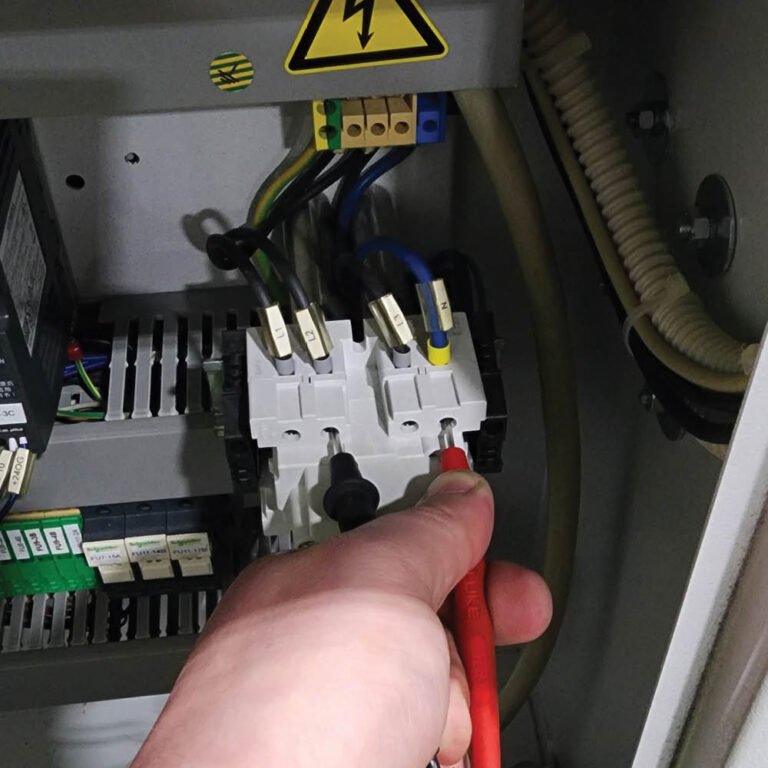

- Troubleshooting & Diagnostics: Fast, clear, and accurate problem-solving for electrical and multi-system controls

- Apprentice Training & Team Support: Equip your workforce with the knowledge and tools for long-term success

“When others guess, we diagnose.”

Troubleshooting Services

for Industrial Clients

We specialize in identifying and resolving complex electrical and automation issues quickly and accurately.

Common Industrial

Issues We Solve

- Intermittent power loss in production lines

- Miswired control panels or circuits

- Faulty PLC logic or I/O modules

- Overloaded circuits in high-demand environments

- Equipment not responding to control signals

- Flickering lights or nuisance tripping in industrial lighting systems

- Pneumatic or hydraulic actuators failing to respond to control signals

- Pressure or flow inconsistencies in automated fluid power systems

- Electro-pneumatic and electro-hydraulic control faults impacting machine performance

Diagnostic Guarantee

At Bremer Electric & Automation, we stand behind our commitment to honest, effective service. That’s why we offer a No-Charge Diagnostic Guarantee for initial service calls—because you shouldn’t pay if we can’t pinpoint the problem.

What This Means for You

If we are unable to identify the root cause of your reported electrical issue during the scheduled diagnostic visit, you won’t be billed for that visit.

Limitations & Conditions

To ensure transparency and fairness, this guarantee applies under the following

conditions:

- Valid only for first-time diagnostic visits related to a specific issue

- Covers up to 60 minutes of onsite troubleshooting

- The issue must be accessible and safe to inspect at the time of service

Does Not Apply To

- Intermittent faults

- Failures caused by third-party systems

- Equipment requiring manufacturer support

If a partial diagnosis is achieved (e.g., narrowed down to a faulty component or system), standard diagnostic fees may apply. Bremer Electric & Automation reserves the right to determine whether a reasonable diagnosis has been achieved.

Complimentary Facility Walkthrough

Every new client receives a diagnostic-driven walkthrough that:

- Assess automation, electrical infrastructure, and maintenance practices to reduce downtime.

- Identifies inefficiencies, compliance risks, and integration gaps before they cost you.

- Receive actionable recommendations to streamline operations and extend system life.

Rapid Response Promise

We respond quickly to minimize disruption and keep your business running. Whether it’s a planned upgrade or an urgent repair, you’ll get clear communication, ethical pricing, and professional service.

Real Projects. Real Results.

Case Studies

Bremer Electric & Automation delivers precision troubleshooting and root cause analysis — streamlining operations, preventing downtime, and future‑proofing systems.

Our process isn’t a one‑time success; it’s a repeatable, reliable method applied consistently across three identical automation systems. By combining technical precision with foresight in design, we enable multimillion‑dollar investments to launch seamlessly, protect profitability, and scale for the future.

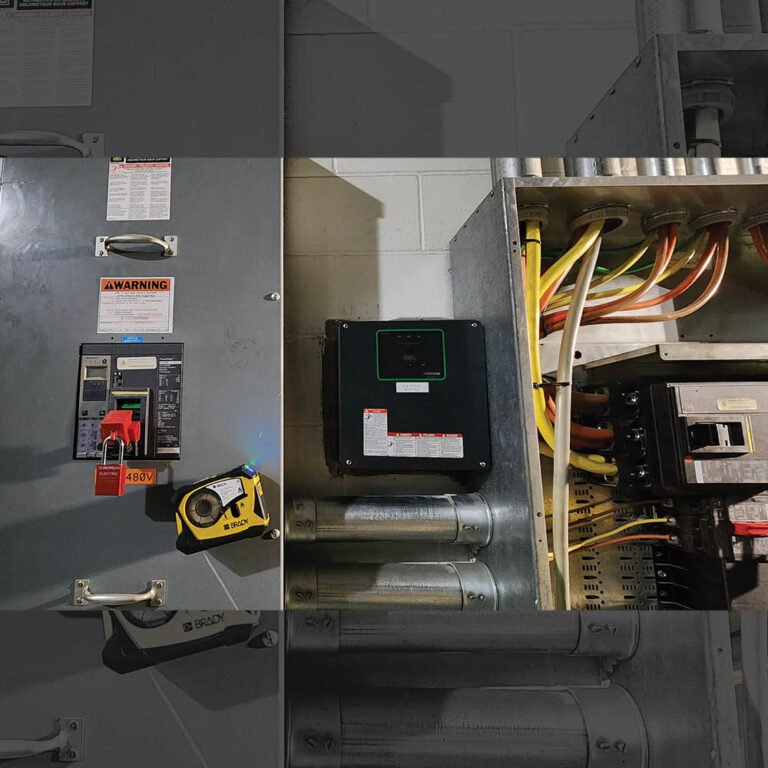

Case Study:

Distribution Panel Upgrade

Challenge

Customer needed reliable 240/120V power for new automation, with room for future expansion.

Solution

Designed and installed a 100A distribution panel with transformer, disconnect, and wiring to support automation systems. Planned for scalability and ensured code‑compliant installation.

Result

Automation brought online with extra panel space for growth. Clean, professional install that aligned with budget.

Impact

● 336 hours of downtime avoided

● At $3,000/hour, that equals $1,008,000 in savings

● Project cost: ~$5,917 (materials $3,500 + labor $2,417)

● ROI ratio: Every $1 invested returned ~$170 in avoided downtime

● Future‑proofed infrastructure reduces risk of costly redesigns

With under $6,000 invested, the client avoided over $1M in losses — a 170:1 return on investment. This project demonstrates how proactive planning and technical precision deliver both immediate functionality and long‑term business value.

Get case studies tailored to your industry.

Trusted by local businesses for ongoing support, upgrades, and troubleshooting.

“Throughout my professional journey, I have had the privilege of collaborating with David on various projects. His exceptional professionalism is evident, but what truly distinguishes him is his remarkable ability to swiftly and efficiently identify and resolve project-impeding challenges. This proactive approach not only mitigates financial burdens but also alleviates the associated stress and frustration for all stakeholders involved.”